VitiFort Optimum™ Plus, the first range of low-carbon steel profiles for vineyards.

ArcelorMittal Tubular Products presents its latest innovation in the viticulture industry: VitiFort Optimum™ Plus, marketed in France under the brand ALqEOS®, the first range of steel profiles for vineyards using low-carbon steel.

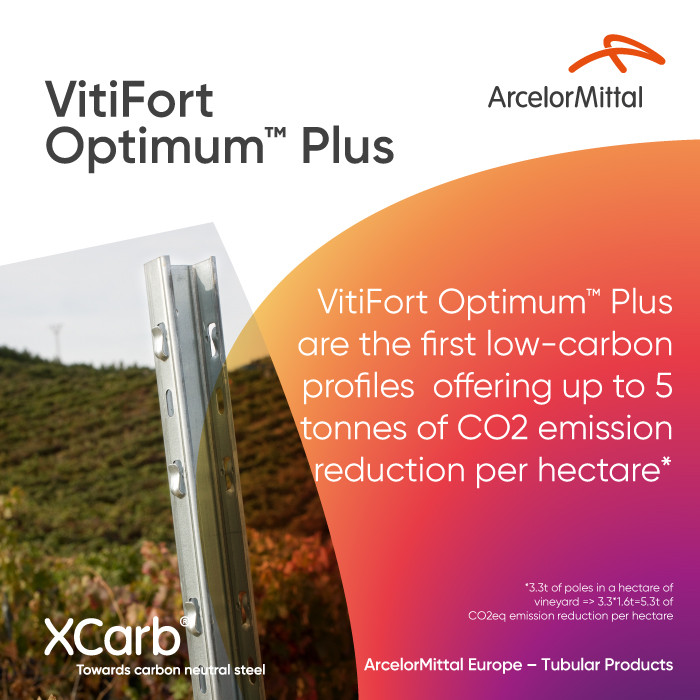

Awarded the Vinitech 2022 Innovation Trophies, VitiFort Optimum™ Plus profiles are made with XCarb® steel produced in the electric furnaces of the ArcelorMittal plant in Sestao, in the Spanish Basque Country, a site that aims to achieve carbon neutrality by 2025. VitiFort Optimum™ Plus profiles are the first low-carbon profiles offering up to 5 tons of CO2 emissions reduction per hectare.

Certified as low-carbon, XCarb® steel benefits from the technological expertise of the ArcelorMittal group, a global leader in steel production, which already produces low-carbon footprint steels. VitiFort® was born from the pooling of the know-how of ArcelorMittal, a global leader in metal and profiling, and professionals in the trellising market who have been working for many years in French, European and global vineyards, alongside distribution and recognized manufacturers. The brand consists of three ranges: VitiFort®, VitiFort Optimum™, and VitiFort Optimum™ Plus. Designed to bring together all of the industrial products and activities related to low, reduced, and zero-carbon steel manufacturing by 2050, as well as broader green initiatives and innovation projects.

VitiFort Optimum™ Plus reinforces ArcelorMittal's commitment to carbon neutrality by 2050.

The advantages of the new VitiFort Optimum™ Plus profiles are:

- CO2 footprint of about 900 kg/T (compared to the usual 2.5T of CO2 emitted in Europe to produce one ton of anti-corrosion coated steel)

- Sendzimir Z-275 zinc coating

- Optimum" zinc-aluminum magnesium coating technology Magnelis®: excellent corrosion resistance